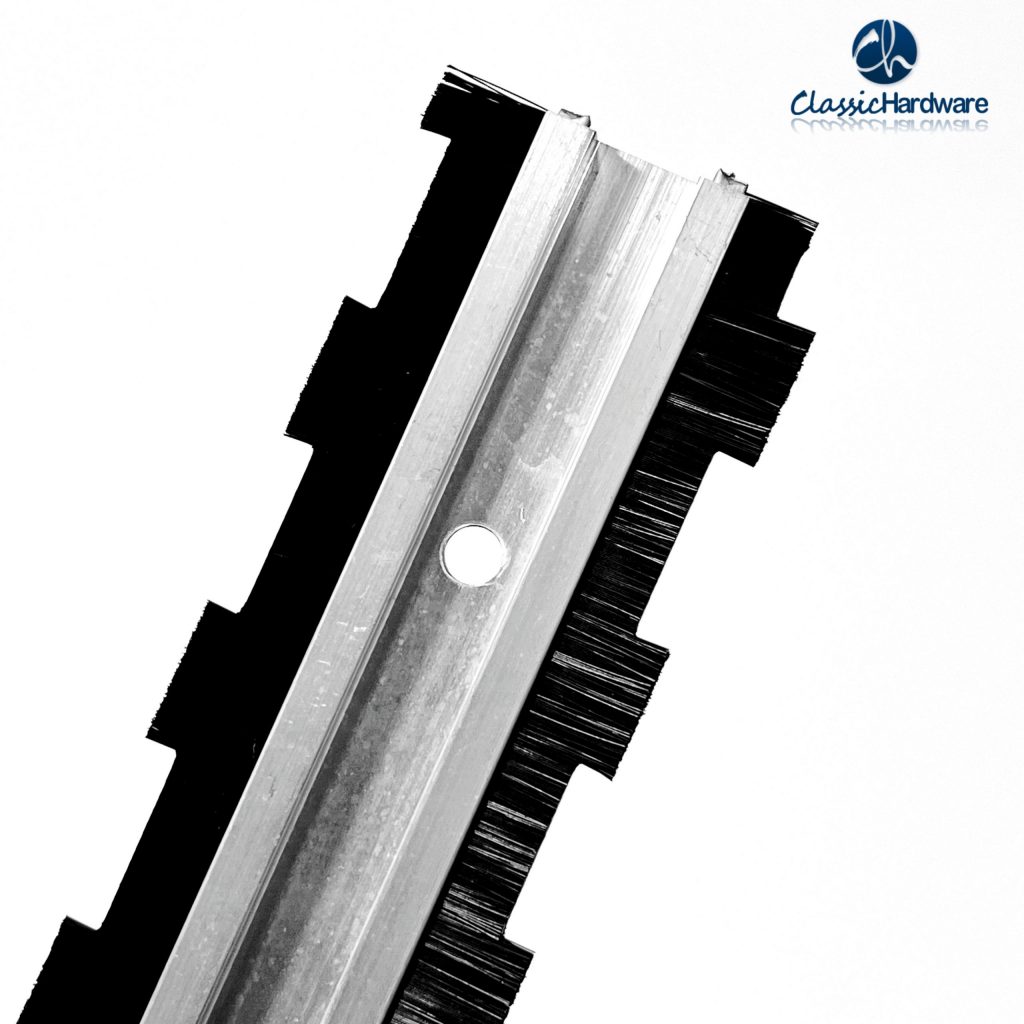

I. Main Applications of Stainless Steel Strip Brushes

The core function of stainless steel strip brushes is cleaning, grinding, polishing, anti-static and transmission. They are widely used in the following fields:

Industrial cleaning and deburring

Cleaning: This is used for cleaning dust, rust, dirt, old paint layers, etc. on the surfaces of bottles, cans, glass, and plates (such as steel plates, aluminum plates, glass plates) on the production line.

Deburring: After mechanical processing, this process is used to remove burrs and sharp edges from the workpiece (such as metal parts, edge of sheet materials), making the edges smooth and meeting precision requirements.

Metalworking and Processing

Surface treatment: This is used for giving a brushed finish to the metal surface, creating a beautiful matte silk-like surface (commonly seen on elevator carriages, electrical panels, and hardware).

Grinding and Polishing: As a primary or secondary grinding tool, it is used to polish the weld seam, remove oxide scale and rust, and prepare for the next step of spraying or electroplating.

Food Processing and Agriculture

Cleaning: In the food industry, stainless steel scrubbers that meet hygiene standards are used to clean the surfaces of fruits (such as potatoes, carrots, apples), crabs, abalones, etc. of dirt and impurities.

Peeling: The process of removing the skin from root and stem vegetables.

Wood processing and stone processing

Texture treatment: Used for cleaning the surface of wood, highlighting the natural texture of the wood and creating an antique effect (commonly known as the “steel wool” effect).

Cleaning: This process is used to remove moss and stains from the surface of the stone and to apply an antique finish.

Other Special Applications

Anti-static: In industries such as printing, textiles, and film production, it is used to remove dust from the surface of materials and eliminate static electricity by grounding through metal bristles.

Transmission: Sometimes it is also used as a transmission brush to assist in the transportation of items.

II. The Outstanding Benefits of Stainless Steel Strip Brushes (Why Choose It?)

The main reason for choosing stainless steel strip brushes is the unique advantages brought by the material (stainless steel wire):

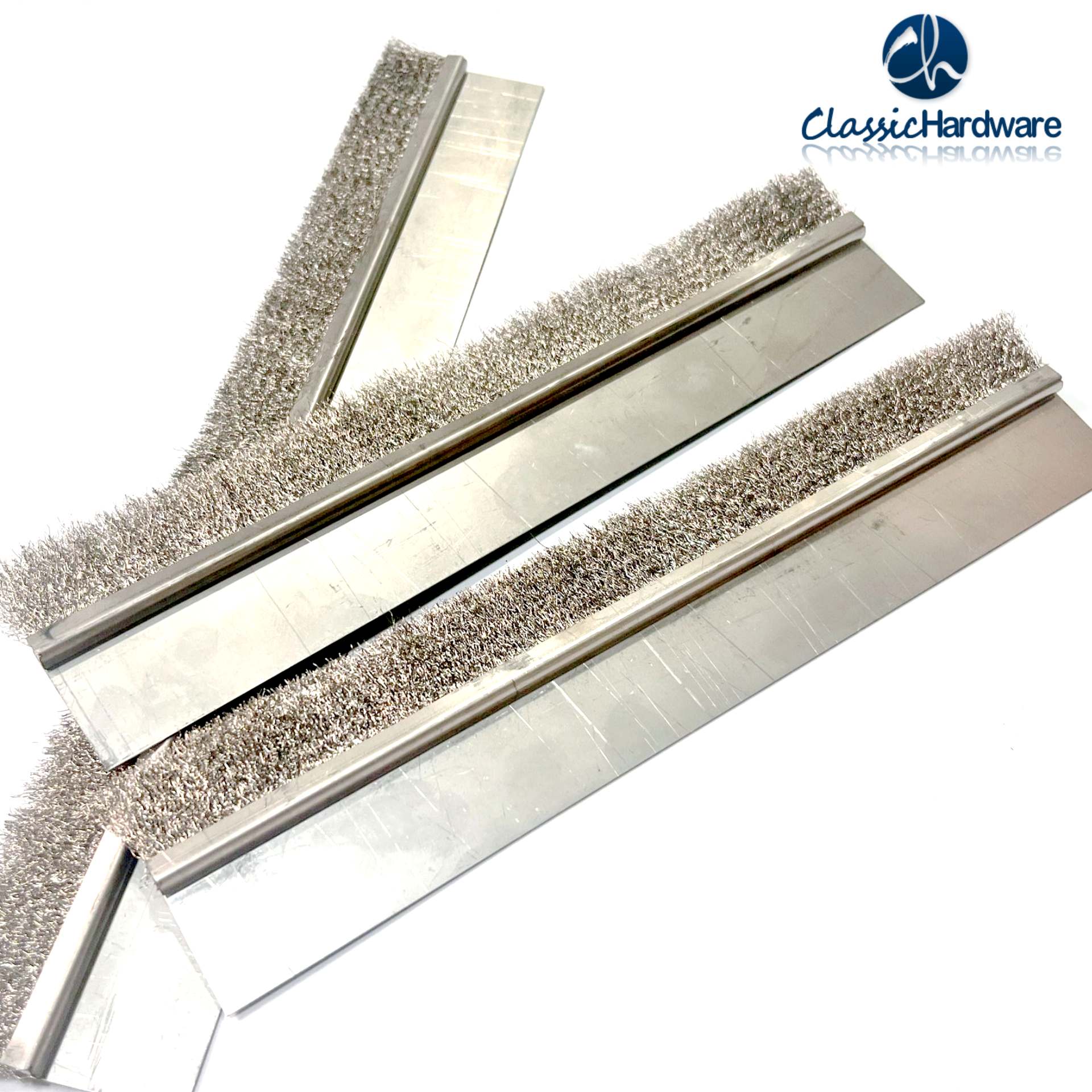

Outstanding corrosion resistance

This is its most crucial advantage. 304 or 316 stainless steel wires can resist corrosion from water, steam, various chemicals and oils. They are highly suitable for use in humid, water-rich or environments with corrosive chemicals (such as in food processing, cleaning industries, and chemical environments), and have an extremely long service life.

High strength and wear resistance

The stainless steel wire is highly hard and has good toughness, making it extremely wear-resistant. When dealing with hard metal burrs, stubborn rust and thick dirt, it is unlikely to break, wear or deform, and can maintain a stable cleaning effect. Its durability is far superior to that of nylon or other plastic brush wires.

Heat resistance

Stainless steel wire can withstand very high temperatures (the specific temperature range varies by model), and unlike plastic brush wires, it will not melt or deform due to high temperatures. This enables it to be used in high-temperature cleaning lines or in situations requiring high-temperature disinfection.

Does not easily cause pollution

In the food and precision manufacturing industries, if the wire brushes fall off, it may cause contamination. The high-quality stainless steel strip brushes are made using a robust process (such as welding), and the wire brushes are firmly fixed, making them unlikely to fall off and thus avoiding the problem of contaminating the products.

Meanwhile, the stainless steel material itself is non-toxic and non-magnetic, meeting the hygiene and safety requirements of the food and pharmaceutical industries.

Good flexibility and consistency

The stainless steel bristles can maintain continuous elasticity and pressure, ensuring stable contact with the workpiece surface, thereby achieving uniform and consistent processing results.

Summary and Purchase Suggestions

In conclusion, stainless steel strip brushes are the preferred tools for high-strength, high-wear, humid or corrosive environments.

When you need:

Handling hard materials such as metals

Working in a humid or cleanable environment

The tool should be extremely durable and have a long lifespan.

Needs to meet food hygiene standards