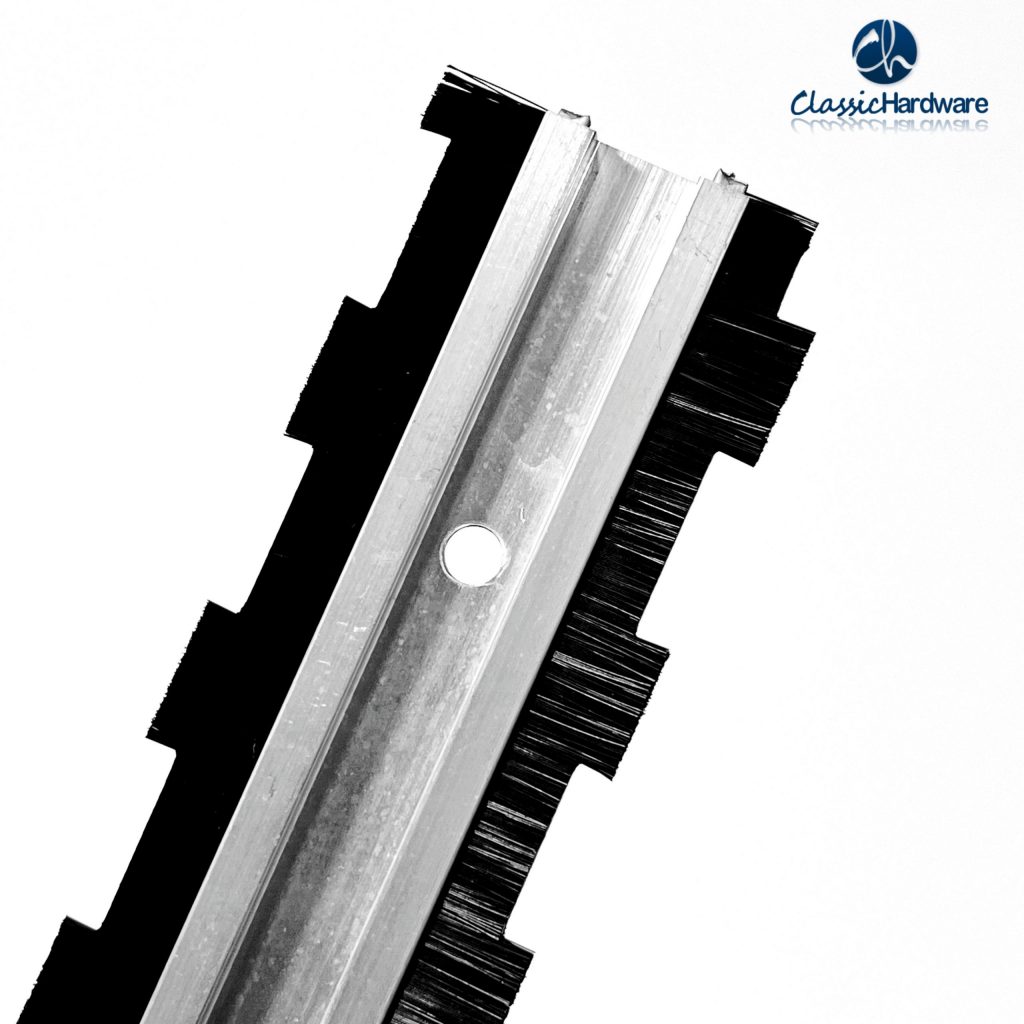

Rubber strip brush: the “invisible guard” of guarding the border, making sealing and cleaning more efficient

In the countless details of industry and life, there are always some seemingly insignificant but crucial existence — they silently undertake the mission of sealing, cleaning and dustproof, becoming a key link in the stable operation of equipment or the improvement of life quality. Rubber strip brush, it is such a kind of “invisible guard”, with its flexibility and wear-resistant characteristics, in machinery, home, transportation and other fields quietly play an irreplaceable role.

One, rubber brush: when flexible and wear resistance perfect integration

The core of rubber strip brush lies in its unique material structure:

High elastic rubber substrate: natural rubber or silicone, both flexible and resilient, can be closely fitted to irregular surfaces, to fill gaps.

Composite fiber reinforcement: embedded polyester or nylon fiber, improve tear strength, avoid deformation and fracture caused by frequent friction.

Surface treatment process: some high-end products add wear-resistant coating (such as polyurethane), life extension of more than 3 times.

Application scenarios: door and window sealing strip, conveyor belt edge cleaning, automatic equipment dustproof, vehicle windshield wiper, etc.

Two, why choose rubber brush? Analysis of four core advantages

- Seal leakproof, watertight

Whether it is a dusty factory environment, or the sound insulation needs of home doors and Windows, rubber brush can close the gap through adaptive deformation.

Data speak: After testing, 0.5mm thickness of silica gel brush can withstand 10kPa pressure difference, isolated more than 90% PM2.5 particles.

- Quiet shock absorption, protect comfort

The damping properties of rubber can effectively absorb vibration and noise.

Case: A car brand embedded rubber brush in the door seal, driving noise reduction of 15 decibels.

- Efficient cleaning, multi-use with one brush

The continuous scraping design of the brush removes stubborn stains while avoiding damage to the surface.

Industrial application: rubber brushes are installed on both sides of the conveyor belt in food factories, and the clearance rate of residual materials is improved to 99%.

- Strong weather resistance, no fear of extreme environment

Temperature range: -50℃~150℃ (special silica gel material);

Anti-aging: through UV ultraviolet accelerated aging test, outdoor service life over 5 years.

Three, rubber brush “intelligent evolution”

With the upgrading of technology, rubber strip brushes are transforming from “functional parts” to “intelligent parts” :

Embedded sensors: real-time monitoring of seal pressure, data linkage equipment early warning system (such as high-speed railway carriage sealing status monitoring);

Environmentally friendly materials: bio-based rubber + recyclable fiber, carbon footprint reduction of 40%, in line with the EU REACH standards;

Modular design: snap installation, replacement without disassembly of the overall structure, maintenance efficiency increased by 70%.

Four, how to choose the right rubber brush? Three steps of accurate matching

Clear requirements: dustproof, waterproof, shock-absorbing or clean? Different scenarios have significant differences in hardness and density requirements.

Measurement parameters: gap width, contact surface roughness, speed and so on determine the size and material of the brush.

Certification verification: food industry FDA certification, high temperature environment to look for SGS temperature report.

V. From factory to life: The “Cross-border Journey” of rubber strip brush

Industrial field: semiconductor workshop anti-static sealing, lithium production line dust isolation;

Transportation: subway shield door edge protection, ship hatch door waterproof seal;

Home scene: cleaning robot side brush upgrade, refrigerator door seal mildew design;

Creative transformation: DIY enthusiasts use it to seal insect screens on balconies and even make leak-proof MATS for pet cages.

Conclusion: Small parts, big value

Rubber brush may never stand in the spotlight, but it is precise protection between the millisecond, for the lasting operation of machinery, clean and peaceful life to provide a solid guarantee. Whether it is the severe challenges in the industrial field or the delicate needs of the home scene, choosing a rubber brush with high adaptability and long life is an “invisible insurance” for efficiency and quality.